News – Sheridan Media

The tools, materials, and knowledge needed to 3D print have advanced quickly, with applications ranging from commercial to home use. Yet University of Wyoming Assistant Professor of Mechanical Engineering Daniel Rau said the technology still suffers from a critical shortcoming: 3D printers currently produce only hard, brittle plastic items. Rau wants to take 3D printing to the next level.

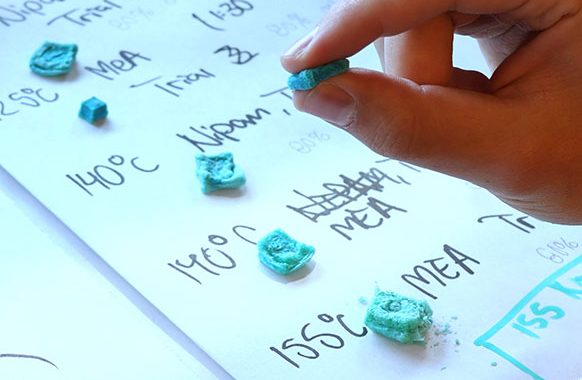

While 3D printing is already useful for creating household items, toys, and mechanical components to exact specifications, current technologies leave a major area untapped—how to make things soft. On the UW campus, Rau’s Additive Manufacturing Lab (RAM Lab) is working to close this gap with help from a nearly $199,000 grant from the National Science Foundation (NSF) for engineering research initiation.

During an appearance on Sheridan Media’s Public Pulse, UW Director of Institutional Communications Chad Baldwin said the NSF program is designed to help new university faculty launch their research by covering expenses and student stipends.

C. Baldwin

Rau, who joined UW’s Department of Mechanical Engineering in fall 2024, will use the award to study why current additive manufacturing processes—the technical name for 3D printing—produce warped blobs instead of stable, functional products when attempting to print elastomers. These materials are more flexible, stretchy, and rubber-like. His research project is titled Improving the Vat Photopolymerization 3D-Printing of Soft Elastomers Through a Deeper Understanding of Process Dynamics.

With the insights gained from these experiments, Rau intends to produce a type of recipe book to guide manufacturing processes for soft materials. Successfully mobilizing this technology could have a significant impact on daily life, particularly in the biomedical industry.

Learn more by clicking here.

Last modified: September 2, 2025